We Offer Solutions to Customers That Need HIGH VOLUME PRECISION MANUFACTURING

Industries We Serve

View All >

Medical/Pharmaceutical

Medical and pharmaceutical products play a vital role in the health and safety of patients. As such, ensuring the quality of each product and its individual components throughout the manufacturing process is essential.

Food/Beverage

The food and beverage industry is heavily regulated to ensure all parts comply with safety standards. As such, manufacturers use food-grade plastic materials for part design and construction, including plastic injection molding.

Window/Doors

We provide innovative product solutions for the window and door industry. Our custom plastic injection molding capabilities are second to none in their ability to create top-quality component parts.

Construction

In the construction industry, one of the keys to successful projects is investing in high-quality construction components, including injection molded plastic building products and assemblies.

Why Choose Rodon

-

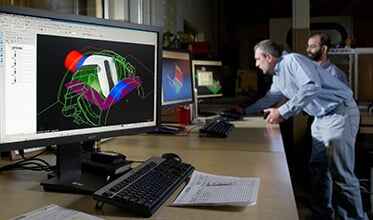

Automation & Robotics

We manufacture injection molded components with quality and precision. Using design software and over 125 presses automated machines in our state-of-the-art robotics facility; we serve a variety of industries including medical/pharma, food/beverage and point of purchase display.

-

Cost-Effective & Quick to Market

Our team has over 65 years of experience providing quality solutions. We are proud to say that our parts are less expensive and quicker to market than those from overseas. Plus, we eliminate offshore risks such as quality and communication issues.

-

Team of American Craftsmen

We’re a third-generation family business with an entirely domestic supply chain, providing turnkey operations for high-volume plastic injection molded parts.

-

Full-Service Innovative Solutions

Our goal is to make our clients’ jobs easier by providing innovative solutions for part designs, tool making and high-volume parts manufacturing.

Recommended Resources:

- eBooks

An Intro to Plastic Injection Molding

Download

Trends, Projections and Benefits of Reshoring

Download

The Benefits of Working with a Turnkey Manufacturer

Download

The ROI of a Full Service Manufacturer

Download

Plastic Injection Molding Solutions for the Food & Beverage Industry

Download

Plastic Injection Molding Solutions for the Medical Industry

Download - Videos

Clean Room Injection Molding | The Rodon Group/Sterling Healthcare

Watch Our VideoAbout Our Company

Watch Our VideoThe Rodon Group Capabilities

Watch Our VideoAbout the Rodon Group

Watch Our VideoRodon's Made in the USA Custom Plastic Injection Molding

Watch Our Video - Case Studies

Polystyrene Diagnostic Kit for the Medical Industry

Learn More

Custom Beverage Cap for the Food & Beverage Industry

Learn More

Residential Window Hardware

Learn More

Cancer Center Partnership: One-Piece COVID-19 Swabs

Learn More - Interactive Infographic

Offshoring vs. Reshoring

Understanding the Risks Before Choosing a Manufacturing Partner

Explore Our Interactive Infographic

Your Component Source in the Domestic Supply Chain

An in-depth look at our full range of capabilities and manufacturing experience

Explore Our Interactive Infographic

Plastic Injection Molding Process

Our new interactive infographic shows exactly how this process works.

Explore Our Interactive Infographic

Rodon’s Innovative Manufacturing Solutions

When selecting a plastic injection molder, there’s a number of different options available–which makes choosing the right one for your needs

Explore Our Interactive Infographic

Have a Custom Project?

Request a QuoteLooking for a Standard Part?

Shop Our CatalogLatest Blog Updates:

How to Build a Mold for Your Custom Plastic...

Manufacturers use a wide range of different molding techniques to create different components and...

10 Tips for Tooling Plastic Parts

A perfect, precision part begins with the mold. Building the tool takes time and a great deal of...

Read More >Plastic Molding 101: Understanding Types,...

Plastic Injection Molding Explained

In manufacturing, molding refers to the process of shaping a...