Excuses, excuses, excuses.

“We can’t ask our employees to sort their trash.”

“We don’t recycle because it all ends up in the landfill anyway.”

“It could end up costing us time and money.”

There is a long list of excuses often espoused by organizations to justify their hesitancy to become involved in recycling programs. Most often these excuses are based on old myths, technologies and processes. Today, recycling and waste collection companies have refined their procedures to offer hassle free, mutually beneficial recycling relationships with businesses throughout the country.

One stream or two?

Gone are the days of containers for every form of trash. Many waste companies now offer either dual-stream or single stream recycling. Dual stream recycling separates paper from all other forms of recyclable material. This method helps increase compliance and collection speeds. Single stream recycling was introduced in the late 1990’s partly in response low recycling rates within communities and organizations. This method allows all recyclable material to go into one container. The material is sent to a sorting facility. Using lasers, conveyor belts and other equipment; various plastics, metals and paper are sorted and baled.

Make electricity not trash.

Make electricity not trash.

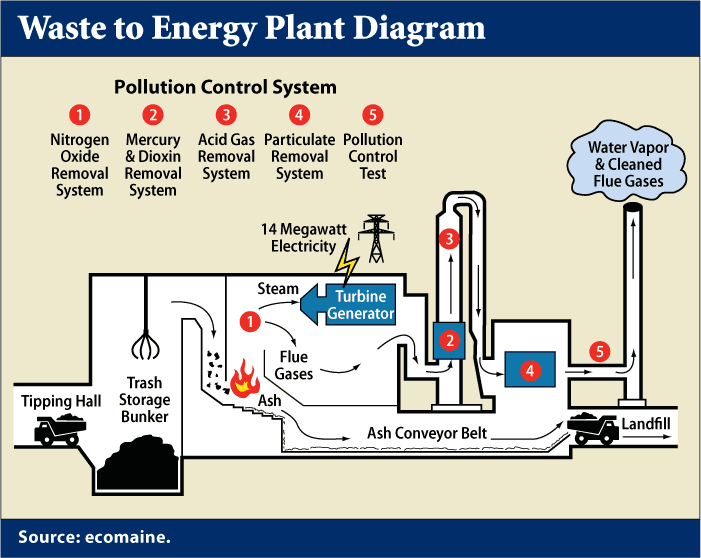

In Europe, countries have been creating energy from trash for a very long time. In this country, the practice is fairly recent, and we are capitalizing on the innovations and successes of our European allies. Many trash-to-steam plants have been built across the country. These plants take just about any material, burn it at extremely high temperatures, heat water which converts to steam. The steam is piped into generators to create electricity.

Many modern landfills are also equipped with energy creating technology. Most commonly landfills have basins that collect methane gas, which can be cleaned and used to generate electricity and fuel alternatives for industries and municipalities.

Organic food disposal.

The latest development in the world of waste recycling is the large scale implementation of organic composting facilities. These plants use a variety of techniques to turn food waste into compost which can be packaged or sold in bulk once the processing has been completed. Supermarkets, restaurants and food wholesalers have all welcomed this disposal alternative.

How does The Rodon Group fulfill their commitment to recycling?

Like many manufacturing companies, we understand the importance of being an environmentally responsible business. Our waste disposal partner, Sustainable Waste Solutions offers a variety of disposal programs from trash to steam, single stream recycling and electronics recycling. Along with our energy initiatives, The Rodon Group believes every business has an obligation to be stewards of our environment and good corporate citizens. We are proud to be designated a “Landfill-Free Enterprise.” Our customers, suppliers and employees all understand the importance of our commitment to recycling and minimizing our impact on the local community and beyond.

Comments