Advancements in plastic injection molding technology allow manufacturers greater flexibility and sophistication in part design. At The Rodon Group, we are continually incorporating the newest technologies to remain on the cutting-edge of molding techniques in all sectors. This commitment to growth and innovation has allowed us to continue providing the highest-quality products to our customers.

At The Rodon Group, we are dedicated to maintaining the health and vitality of the environment. We firmly believe that every business holds a societal obligation to implement green manufacturing initiatives aimed towards fostering sustainability and minimizing the impact on the local community and environment.

Earth Day, observed each year on April 22, serves as a celebration of the birth of the modern environmental movement. Started in 1970, Earth Day was sparked by the country’s burgeoning understanding of how contemporary industrial practices were negatively impacting the environment. The celebration was designed to bring awareness to many of the dangers affecting the environment — air pollution, water contamination, habitat destruction, and so on — and to encourage people to take action in protecting their surroundings.

Sustainability in Manufacturing

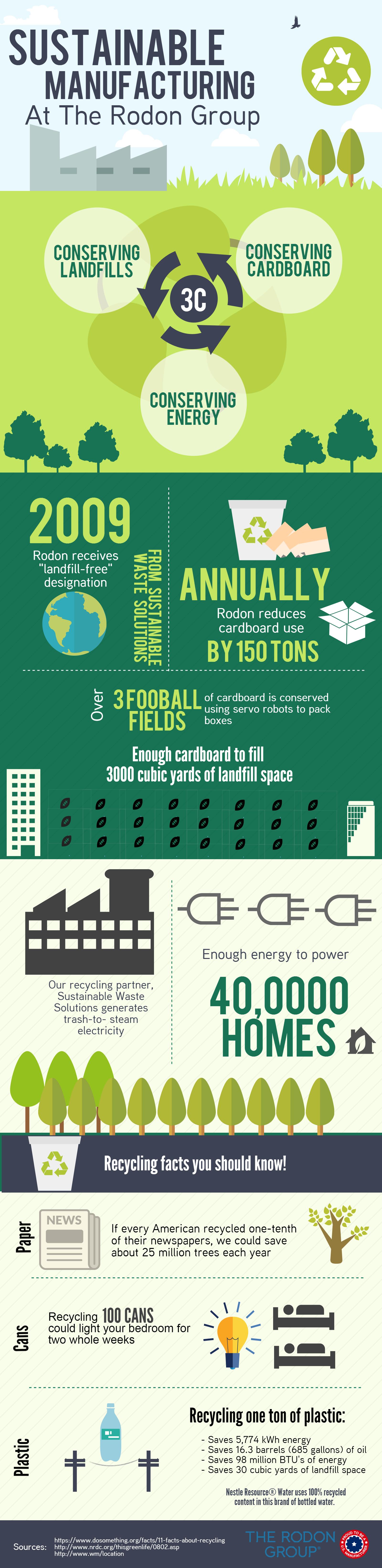

In celebration of Earth Day this week, we created an infographic showing how we tackle sustainable manufacturing at Rodon. The processes we use in our facility help to minimize packaging, transportation costs, waste, water consumption and energy.

Tell us in the comments section below what efforts your company uses to remain a sustainable business.

In today’s world, the green movement is more important than ever. No matter what the industry, it’s a company’s responsibility to make changes and choices that support the environment.When you’re looking for a plastic injection molding company, there are several things you can check for to be sure you’ll be working with an environmentally responsible business.

Certification

ISO 9001 Certification is a way for companies to keep a close eye on their production processes. Meeting the International Standards for Quality Management ensures the company has been thoroughly audited and is fully in control of its’ procedures so that no part of the production process “slips through the cracks.”

Waste Reduction

Make sure the company you work with is minimizing waste. During the molding process, excess plastic is generated. What does the company you work with do with it? Look for a company that has a system to recycle all excess plastic.

What about boxes? The efforts of cardboard recycling make a huge difference. At Rodon, we conserve 150 tons of cardboard per year, enough to fill 3000 cubic yards of landfill space or 3 football fields about a foot deep! Using servo robots to incrementally stack parts, we reduce part distortion while tripling or quadrupling the number of parts packed into the same size carton. Rodon's customers are also offered a returnable/reusable packaging program to further reduce cardboard use

Sustainability in Manufacturing

Each year, we stop to remember the humble beginnings of Earth Day and how the movement has grown over the past forty-four years since its inception. Back in the early days, the Vietnam War nearly consumed the American conscious. Not much room remained for environmental causes.

American Manufacturing and Products

Excuses, excuses, excuses.

“We can’t ask our employees to sort their trash.”

“We don’t recycle because it all ends up in the landfill anyway.”

“It could end up costing us time and money.”

There is a long list of excuses often espoused by organizations to justify their hesitancy to become involved in recycling programs. Most often these excuses are based on old myths, technologies and processes. Today, recycling and waste collection companies have refined their procedures to offer hassle free, mutually beneficial recycling relationships with businesses throughout the country.

One stream or two?

Gone are the days of containers for every form of trash. Many waste companies now offer either dual-stream or single stream recycling. Dual stream recycling separates paper from all other forms of recyclable material. This method helps increase compliance and collection speeds. Single stream recycling was introduced in the late 1990’s partly in response low recycling rates within communities and organizations. This method allows all recyclable material to go into one container. The material is sent to a sorting facility. Using lasers, conveyor belts and other equipment; various plastics, metals and paper are sorted and baled.

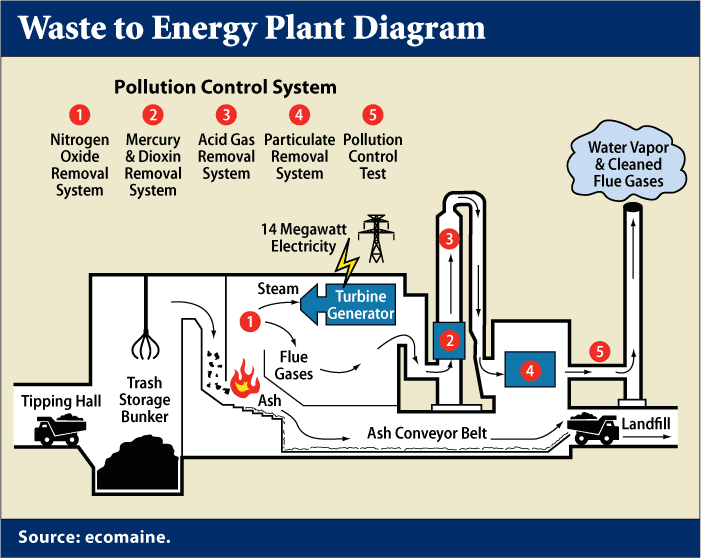

Make electricity not trash.

In Europe, countries have been creating energy from trash for a very long time. In this country, the practice is fairly recent, and we are capitalizing on the innovations and successes of our European allies. Many trash-to-steam plants have been built across the country. These plants take just about any material, burn it at extremely high temperatures, heat water which converts to steam. The steam is piped into generators to create electricity.