Once in a while, you find a video that is so well done, so compelling, that you must share. This video, from American Made Matters is a great example. It will make you think twice about where products are made; knowing that the simple act of buying American-made products can have a profound impact on our economy. It's all about creating jobs. Jobs that are secure and well-paying. Jobs that can help re-build our middle class.

American Manufacturing and Products

This article written by the Reshoring Initiative Editorial Team originally appeared on the Reshore Now blog on October 15, 2014

It is no secret that the last decade has brought a surge in demand for products made in the USA. But it was only recently we realized how much the “Buy American” movement has evolved.

In a recent survey conducted by American Certified, 1500 people across the nation were asked the question, “Other than price/ quality, what factor is most important to you when purchasing a product?”

Pennsylvania has a long history of industrial and manufacturing firsts. Scranton, in the northeastern part of the state was the first city in America to be electrified. Titusville, Pennsylvania was the birthplace of the oil industry. Iron production first began in this state in 1716 and within 100 years coal was fueling industrial growth.

Manufacturers benefited from all of this industrial development. Philadelphia and Pittsburgh established themselves as hubs. Philadelphia became known for manufacturing textiles, chemicals, metals, furniture and pharmaceuticals. Ship building was one of the first major industries for this port city. The western city of Pittsburgh became known for heavier industries including iron and steel production. It was also the birthplace of the H.J. Heinz Company, makers of the ubiquitous iconic condiment we have all grown to know and love today, Heinz Ketchup.

Since 1956, The Rodon Group has made billions of American made products in our 125,000 square foot facility, including over 32 billion parts for the K'NEX construction toy system.

K'NEX is the only construction toy company committed to manufacturing in the United States. K'NEX bricks,rods and connectors are manufactured in Pennsylvania right here at our eco-friendly facility. K'NEX and Rodon are proud to be family owned and operated. While most toys are made overseas, we are committed to manufacturing in the United States

"Community is one of our core values, so as a company, we are proud to invest in American workers who demonstrate unparalleled commitment to innovation and some of the greatest working spirit in the industrial world," said Michael Araten, President and CEO of K'NEX and The Rodon Group.

American Manufacturing and Products

Excuses, excuses, excuses.

“We can’t ask our employees to sort their trash.”

“We don’t recycle because it all ends up in the landfill anyway.”

“It could end up costing us time and money.”

There is a long list of excuses often espoused by organizations to justify their hesitancy to become involved in recycling programs. Most often these excuses are based on old myths, technologies and processes. Today, recycling and waste collection companies have refined their procedures to offer hassle free, mutually beneficial recycling relationships with businesses throughout the country.

One stream or two?

Gone are the days of containers for every form of trash. Many waste companies now offer either dual-stream or single stream recycling. Dual stream recycling separates paper from all other forms of recyclable material. This method helps increase compliance and collection speeds. Single stream recycling was introduced in the late 1990’s partly in response low recycling rates within communities and organizations. This method allows all recyclable material to go into one container. The material is sent to a sorting facility. Using lasers, conveyor belts and other equipment; various plastics, metals and paper are sorted and baled.

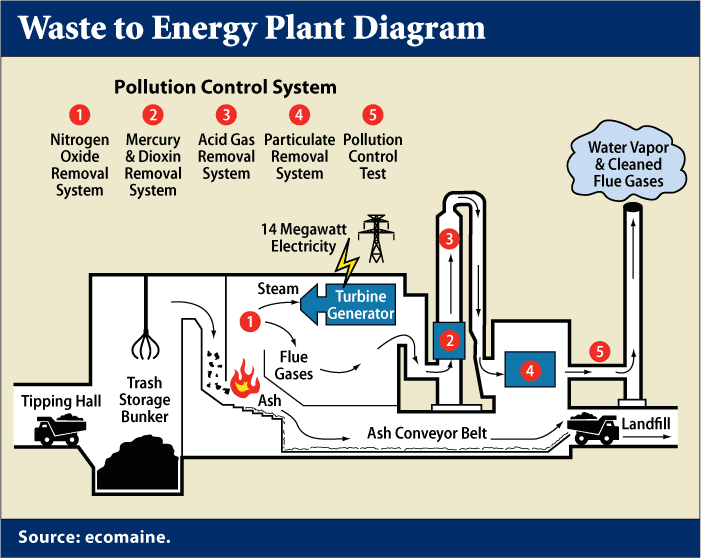

Make electricity not trash.

In Europe, countries have been creating energy from trash for a very long time. In this country, the practice is fairly recent, and we are capitalizing on the innovations and successes of our European allies. Many trash-to-steam plants have been built across the country. These plants take just about any material, burn it at extremely high temperatures, heat water which converts to steam. The steam is piped into generators to create electricity.

Worlds Kids Love: Created Daily at Hatfield, PA Toy Manufacturer

Amazement. K’NEX President and CEO Michael Araten says that it is one of the most common reactions he receives when he tells people that K’NEX building toys are manufactured in Hatfield, Pennsylvania. “So many people are used to toys from overseas that they don’t even consider that these products may be manufactured not just in the United States, but in their own backyard,” Araten said. “That is the perception that we’re hoping to change.”

If amazement is the initial response to the news that K’NEX products are manufactured in Hatfield, PA, the sentiment only deepens upon hearing the uniquely American story behind the colorful plastic building sets.

American Manufacturing and Products

When I first arrived at K’NEX in 2006 I was asked to outline a vision for growth. As president and CEO, I had to find a way to blend the culture of the toy business with our manufacturing business, The Rodon Group.

The two companies never really had a joint vision before so, in order to encourage growth in both organizations, I realized I would have to create a strategic plan that would move both companies forward yet maintain their separate agendas.

As I sought input from our nearly 200 employees and received advice from outside agencies, I realized that the key to a successful plan was to carefully craft objectives and then monitor progress towards them to ensure that our actions were effective.